Plasma-catalyst: A green approach for nitrogen fixation

B. Sadeghi1,2, R. Snyders2,3, M. P. Delphancke1

1 4MAT Department, Université libre de Bruxelles

2 Chimie des Interactions PlasmaSurface (ChIPS), Université de Mons

3 Materia Nova Research Center, Parc Initialis, Mons

Nitrogen fixation (NF) is a process converting molecular nitrogen into valuable chemicals, such as NH3 or NOx, which are the feedstock for various industrial products1. Commercial NF process is associated with high energy consumption and dramatic environmental drawback. In quest to amendment NF process, plasma-assisted NF is a highly promising cost-effective approach when considering the utilization of intermittent green energy sources. Numerous efforts have been spent aiming at maximizing the production yield and minimizing its corresponding energy cost2. On the other hand, plasma-catalytic processes are considered a green method compared to the conventional chemical industry since it relies on the sustainable electrifying operation3. In this context, plasma-catalytic NF process has recently been the object of academic attention4. Most research projects focus on enhancing the synergy between the plasma and the catalyst through exploiting the reaction mechanisms involved. Plasma-catalytic processes, however, remain still ambiguous in the field of NF.

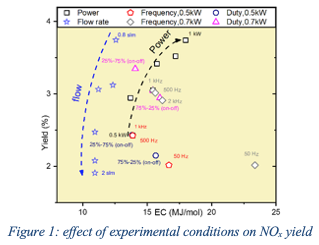

Results on catalyst-assisted microwave plasma NF in the post-discharge zone will be presented. The heterogeneous catalysts made of transient metal oxides (nano layer or nano crystallites) supported on γ-alumina were prepared and characterized by different techniques. The effect of the catalysts composition as well as the effect of plasma parameters such as the feed gas ratio and the flow rate on the NOx production and the energy consumption are studied. To understand the undergoing mechanism, the structural and physicochemical properties of the catalysts along with plasma discharge properties are correlated to NOx production. Our FTIR studies show NOx formation can be significantly influenced and eventually optimized either by the experimental conditions or by the catalysts tuning.

This research is supported by the FNRS project “NITROPLASM”, EOS O005118F.

References:

- Cherkasov, N. et al., Chem. Eng. Process. Process Intensif, (2015), 90, 24–33.