-

Share this page

P15-Bagherpour

Dual-phase CuZr thin film metallic glasses (TFMGs) deposited by PVD magnetron sputtering: bias voltage and thickness dependency of structure, hardness, and wear resistance

A. Bagherpour a*, MS. Colla b, A. Orekhov c, T. Pardoen b, S. Lucas a

a Laboratoire d’Analyse par Réaction Nucléaires (LARN), Namur Institute of Structured Matter (NISM), University of Namur, 61 Rue de Bruxelles, 5000 Namur, Belgium

b Institute of Mechanics, Materials and Civil Engineering (iMMC), UCLouvain, Place Sainte Barbe 2, bte L502.02, B-1348, Louvain-la-Neuve, Belgium

c EMAT, University of Antwerp, Groenenborgerlaan 171, B-2020, Antwerp, Belgium

E-mail: alireza.bagherpour@unamur.be

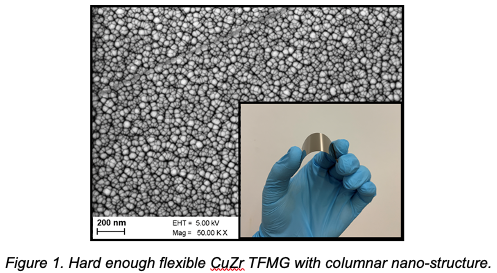

Bulk metallic glasses (BMGs) show appealing mechanical properties including high hardness, desirable corrosion resistivity, and thermal characteristics [1],[2]. BMGs suffer from brittleness due to their short-range structure and lack of the dislocation-like crystalline defects. The thin film configuration (TFMGs) has received a lot of attraction in recent decades due to additional interesting properties as high strength, ductility sometimes beyond 10%, and notable corrosion and wear resistance [3],[4]. In this study, the structure of novel multilayered dual-phase CuZr TFMGs deposited by PVD magnetron sputtering are compared for different deposition conditions (0 V, -100 V, -150 V, -200 V bias voltage) and various coating thicknesses (230 nm, 420 nm, 620 nm, 700 nm). Films characterization has been done by XRD, SEM, TEM, XPS, and Profilometer. Hardness and wear resistance relative to deposition conditions were studied by nano-indentation and pin-on-disc respectively. According to our observation, increasing bias voltage act as a double edge sword: it leads to an increase in mechanical properties then decreases above 150V. Higher thickness leads to a decline in mechanical properties. Overall, the best mechanical properties were achieved for -150 V bias and below 500 nm dual-phase metallic glass thin film.

[1] J. P. Chu et al., “Thin film metallic glasses: Unique properties and potential applications,” Thin Solid Films, vol. 520, no. 16, pp. 5097–5122, 2012.

[2] M. F. Ashby and A. L. Greer, “Metallic glasses as structural materials,” Scr. Mater., vol. 54, no. 3, pp. 321–326, Feb. 2006.

[3] M. Ghidelli, S. Gravier, J. J. Blandin, T. Pardoen, J. P. Raskin, and F. Mompiou, “Compositional-induced structural change in ZrxNi100-x thin film metallic glasses,” J. Alloys Compd., vol. 615, no. S1, pp. S348–S351, Jan. 2015.

[4] M. Apreutesei, P. Steyer, A. Billard, L. Joly-Pottuz, and C. Esnouf, “Zr-Cu thin film metallic glasses: An assessment of the thermal stability and phases’ transformation mechanisms,” J. Alloys Compd., vol. 619, pp. 284–292, 2015.