Nanowire based dynamic emissivity switch fabric for dual-mode temperature regulation

M. G. Abebe1, J. Geltmeyer2, E. Schoolaert2, K. De Clerck2, and B. Maes1

1Micro- and Nanophotonic Materials Group, Research Institute for Materials Science and Engineering, University of Mons

2Department of Materials, Textiles and Chemical Engineering (MaTCh), Ghent University

Mulunehgeremew.abebe@umons.ac.be

Natural disasters due to extreme weather conditions have become frequent events in some parts of the world. There is mounting evidence that these events relate to climate change and global warming. As far as humankind is concerned, global warming imposes a severe existential threat and has to be addressed. Out of the total global energy consumption, a substantial amount (50%) is used in commercial and residential buildings for heating and cooling purpose. Interestingly, we continuously heat and cool large buildings in order to keep the occupants in thermal comfort, while there is no difference in energy consumption between a few or many occupants. Thus, a large amount of energy is wasted, activating an ongoing effort to reduce energy consumption. To this end, it is essential to localize the heating and cooling efforts using smart temperature regulating fabrics.

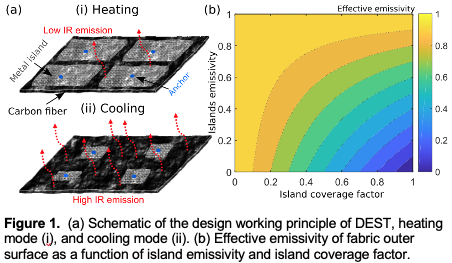

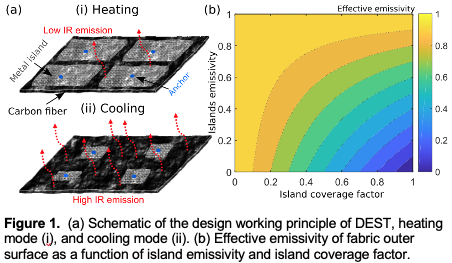

Here, we propose a dynamic emissivity switch textile (DEST) for dual-mode temperature regulation, using the fabrics' outer surface emissivity modulation. The fabric is constituted from a highly emissive bottom layer and low emissive islands on top, which are thermo-mechanically dynamic (Figure 1a). The islands are made from temperature-sensitive shape-memory polymer nanofibers using electrospinning and coated with a metal, while the bottom layer is composed of carbon fibers. The proposed design operates in two modes, heating, and cooling. When the ambient is cold, the fabric is in heating mode, the polymer expands, allowing the low-emissive islands to stretch and cover the high-emissive layer, as shown in Figure 1a(i)). This increases the island-coverage factor (i.e., islands area/bottom layer area) and substantially lowers radiation emission to the ambient (i.e., low effective emissivity, right side of Figure 1b). When the ambient is hot, the fabric is in cooling mode, the polymer shrinks; thus, the low-emissive island surface area reduces, exposing the bottom high-emissive layer to the ambient, as shown in Figure 1a(ii) (low island-coverage factor). This results in a higher effective emissivity of the outer surface, thus strong radiative emission to the ambient (left side of Figure 1b). By introducing an optimized metal coating on the nanofibers, one can achieve an effective emissivity contrast of about 0.8, which translates to a wide ambient setpoint window.

Here, we propose a dynamic emissivity switch textile (DEST) for dual-mode temperature regulation, using the fabrics' outer surface emissivity modulation. The fabric is constituted from a highly emissive bottom layer and low emissive islands on top, which are thermo-mechanically dynamic (Figure 1a). The islands are made from temperature-sensitive shape-memory polymer nanofibers using electrospinning and coated with a metal, while the bottom layer is composed of carbon fibers. The proposed design operates in two modes, heating, and cooling. When the ambient is cold, the fabric is in heating mode, the polymer expands, allowing the low-emissive islands to stretch and cover the high-emissive layer, as shown in Figure 1a(i)). This increases the island-coverage factor (i.e., islands area/bottom layer area) and substantially lowers radiation emission to the ambient (i.e., low effective emissivity, right side of Figure 1b). When the ambient is hot, the fabric is in cooling mode, the polymer shrinks; thus, the low-emissive island surface area reduces, exposing the bottom high-emissive layer to the ambient, as shown in Figure 1a(ii) (low island-coverage factor). This results in a higher effective emissivity of the outer surface, thus strong radiative emission to the ambient (left side of Figure 1b). By introducing an optimized metal coating on the nanofibers, one can achieve an effective emissivity contrast of about 0.8, which translates to a wide ambient setpoint window.

ACKNOWLEDGMENT

We acknowledge support from the INTERREG PHOTONITEX and ARC-21/25 UMONS2 projects.

https://edtmain2023.site.ulb.be/en/program/p28-abebe